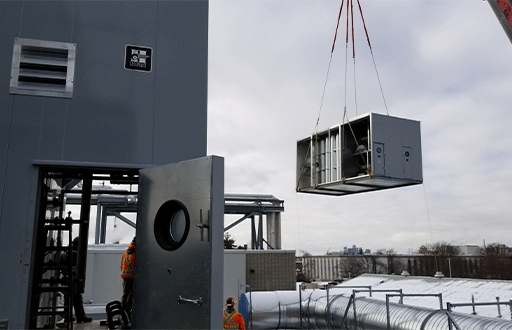

We are proud to have been a part of this biopharmaceutical facility project! Our engineers worked with the mechanical consultant early in the design phase to select the proper equipment for this project. We supplied a custom 32,000 CFM Haakon air handler with multiple energy recovery elements and a service corridor housing both prefabricated and installed steam. We also provided a DriSteem steam generator, ABB variable frequency drives for the supply and exhaust fans as well as a remote DriSteem RO system to feed the steam generator.

HTS supplied the following equipment:

- Haakon AHU

- DriSteem Steam Generator

- ABB Variable Frequency Drives

- DriSteem RO System