Western Memorial Regional Hospital integrated high-performance mechanical solutions to meet the demanding needs of a coastal acute care healthcare environment while supporting energy efficiency and decarbonization goals.

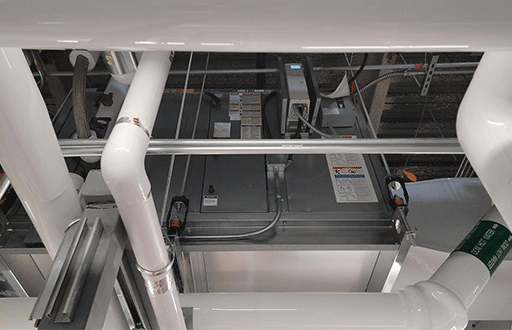

Haakon Air Handling Units were selected for their robust design, energy efficiency, and ability to be tailored to the specific needs of the facility. With reduced face velocity and high-effectiveness enthalpy wheels, the air handlers significantly contributed to the hospital’s decarbonization efforts. These units are designed for low energy consumption during standard operation and are capable of enhanced performance during external events such as forest fires or pandemics, ensuring a safer and healthier indoor environment.

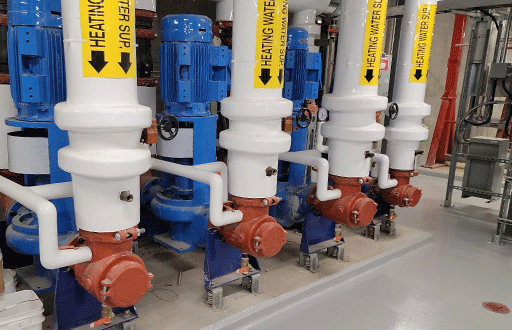

Precision Resistive Steam Boilers were chosen to provide steam for heating, humidification, and sterilization needs. The boilers offered a cost-effective, zero fossil fuel backup solution, contributing further to the facility’s sustainability goals without compromising reliability.

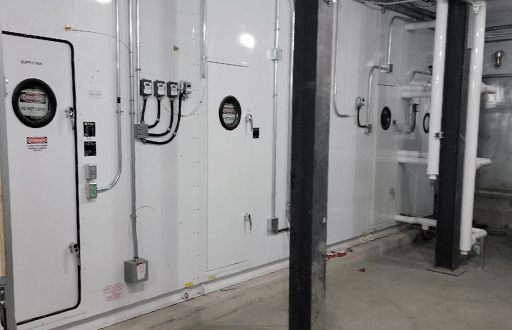

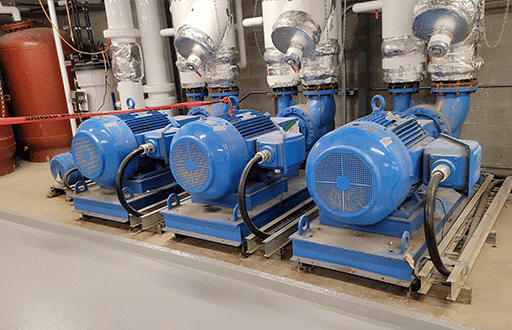

Kinetics Noise Control Vibration Isolators were utilized throughout the building to mitigate vibration and noise concerns for various spaces based on their noise sensitivity. HTS Engineering designed and stamped the seismic restraint systems for the mechanical and air distribution systems, as well as for electrical equipment. HTS certifications were submitted to ensure the facility met post-disaster compliance codes.

Together, these systems demonstrate a forward-thinking approach to healthcare facility design, emphasizing resilience, energy efficiency, and decarbonization.

HTS provided the following equipment:

- Haakon Air Handling Units

- Small Daikin VRV System for Technical Cooling

- Dristeem Ultrasorb MP Steam Humidifiers

- Daikin Precise Line Fancoils

- Daikin Vision Air Handlers

- IEC Fan Coils

- Precision Resistive Steam Boilers